Black Iron Oxide G-330

Black Iron Oxide G-330 Specification

- Molecular Formula

- Synthetic Iron Oxide Pigment

- Place of Origin

- INDIA

- EINECS No

- 215-570-8

- Chemical Name

- Synthetic Iron Oxide Pigment

- Usage

- Car Paint, Furniture Paint, Coating Pigment, Cosmetic Pigment, Ink Pigments, Plastic Pigment, Rubber Pigment, Leather Pigments, Ceramic Pigments, Boat Paint, Building Coating, Paper Coating, Plastic Coating, Road Marking Paint, Rubber Coating

- Type

- POWDER

- Style

- Inorganic Pigment

- Physical State

- Solid

- Application Method

- By Mixing

- Color

- Black

- Purity(%)

- 99

- Application

- Paint,Paver, Masterbatch

- Grade

- G-330

Black Iron Oxide G-330 Trade Information

- Minimum Order Quantity

- 25 Kilogram

- FOB Port

- MUMBAI

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10000 Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

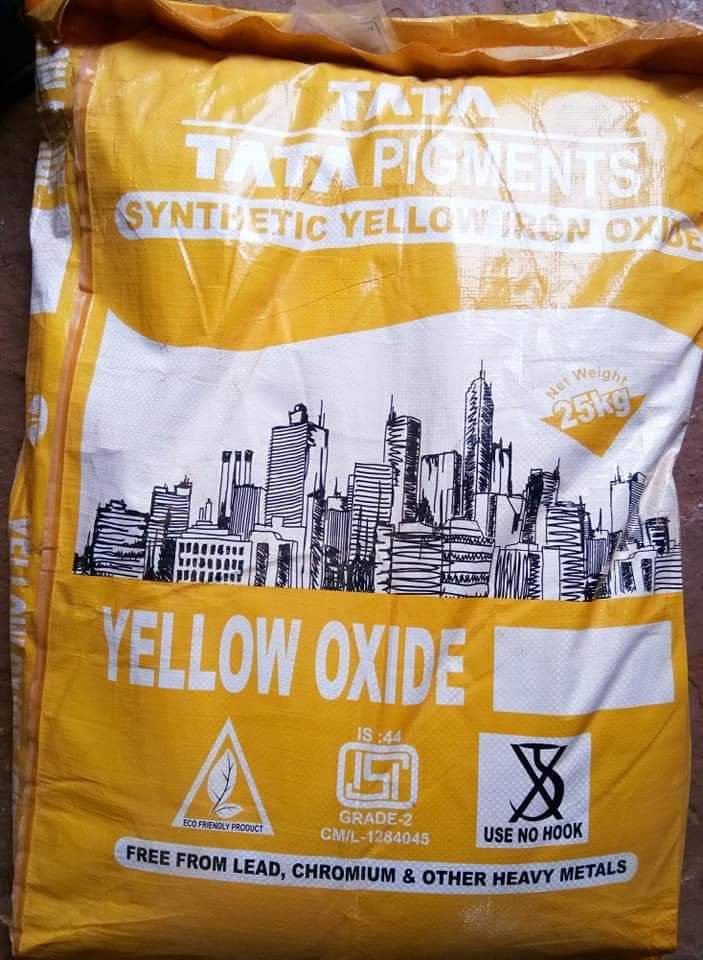

- 25 kgs HDPE Bags with proper Labels of Tat pigments

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- BIS

About Black Iron Oxide G-330

- Tata Black is ideally Suited for flooring and they have the best mobility with cement.

- Resistance to alkali and light fastness are excellent

- Tata Black furnishes the floor with a bright, shiny and smooth surface.

- Tata Black is non toxic and non inflammable

- Tata Black has permanent colour stability and resists fading.

Uses: Tata Black is highly suitable for colouring of cement and mosaic floors, tiles, dadoes, plastic works and colour wash.

Application Procedure: Complete and careful mixing of the Tata Black flooring colours and cement is imperative for best results. Tata Black should be mixed with grey or white cement in the proportion 1:4 or 1:5 (colour of cement), depending upon the desired depth of the colour- [Grey cement is recommended for deep shades and white cement for pastel shades].

Moreover, to eliminate the occurrence of patches and also to produce a smooth and uniform finish, the colorant and cement must be mixed in a dry state before adding water. The mixture has to be applied by trowelling. A 24 hour gap has to be maintained before curing is undertaken for setting.

Precaution:

- For better results, it is necessary to prepare a homogenous mixture of Tata Black and Cement in a dry state beforeadding water.

- The chore of mixing and application must be done by an experienced mason.

- The dry mixture should be prepared just before applying it.

- The wet floor surface must be protected from dust, direct sun light and damage of any other nature.

- Use of chalk powder with the dry mixture of colours and cement must be avoided as it dilutes the intensity of the colour

- Any contact between Tata Pink and acids or acidic materials must be prevented.

- Tata Pink may be used for interior and protected exterior surface only.

- Tata Pink is not recommended for exterior use because of its poor light stability.

Polishing: Buffing and polishing should be undertaken after the floor has been allowed to dry for a week. More time will ensure a better hardening,

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Iron Oxide Pigments Category

Tata Synthetic Blue Oxide Pigment

Price 145.0 INR

Minimum Order Quantity : 25

Grade : Blue

Physical State : Solid

Type : POWDER

Color : Black

Synthetic Brown Iron Oxide Pigment Powder

Price 188 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : Industrial

Physical State : Powder

Type : Synthetic Brown Iron Oxide Pigment Powder

Color : Brown

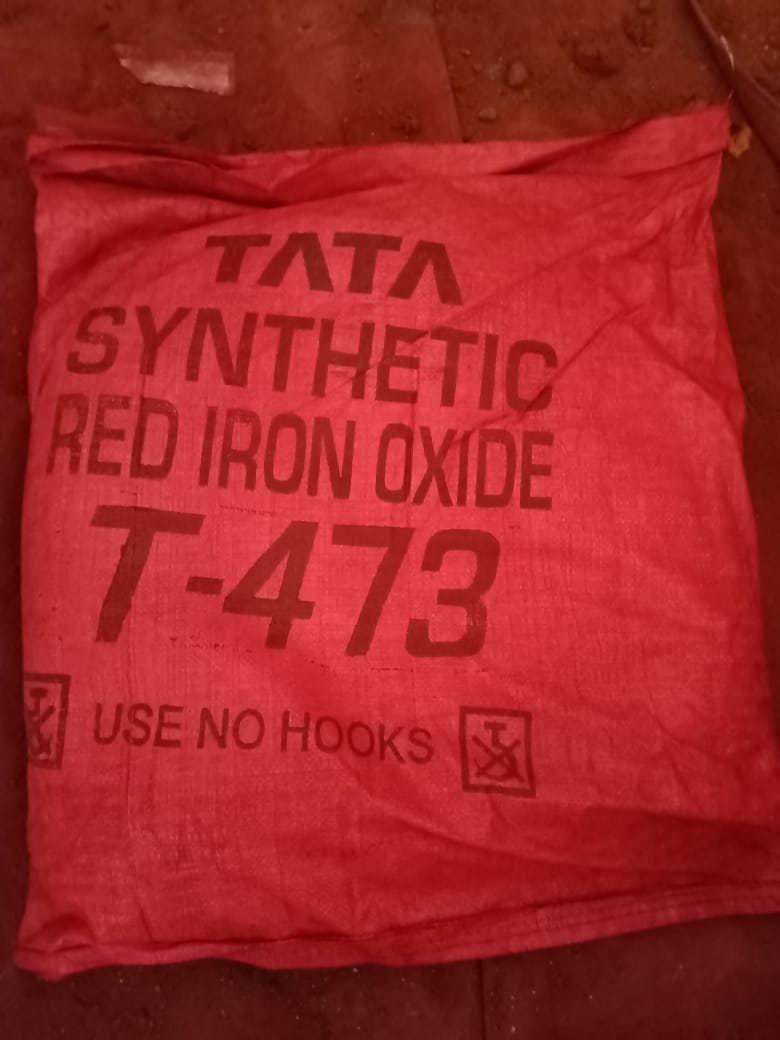

Red TATA Powder Pigment T- 473

Price 115.0 INR

Minimum Order Quantity : 25

Grade : T 473

Physical State : Solid

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese